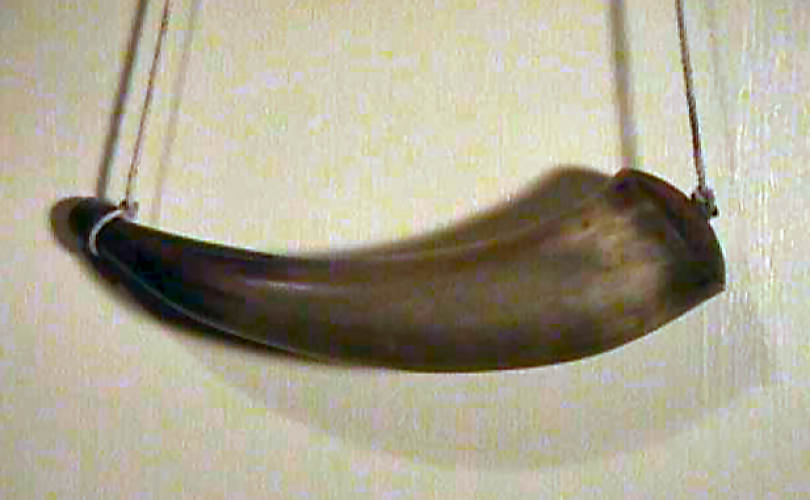

| The Powder Horn was essentially a container, and it was a very efficient container for black powder. An animal horn had an inherently strong structure for containing solid or liquid commodities and was easily transformed into a powder horn. For use as a powder horn, the animal horn had to have its largest end stoppered solidly with a wooden plug and its smallest end cut off in order to allow black powder to be poured in and poured out as needed. A properly constructed powder horn, though, would have another attribute: the wall of the horn would be shaved to the point where it would thin enough to see the powder within, but not so thin that it would be easily broken. A bull's or oxen's horns were not completely hollow. There was a portion at the base of the horn, which contained a grisly cartilage material. To make a basic powder horn, the hornsmith would cut off a portion of the larger end of a bull's or oxen's horn to get rid of the grissly material. He would trim the edge to make it neat and even. A wooden plug would be whittled to fit into the large end of the horn. The plug would then be tacked with small nails to hold it in place. Although it is not a foolproof method of dating powder horns, ones with only a few (four to five) tacks holding the wooden plug in place might be accurately identified as ones dating to the 1700s. There was no reason to waste precious metal tacks when a few would suffice. In later years, into the mid-1800s, when metal tacks were less expensive, the hornsmith could afford to place them all around the horn's edge. After placing and attaching the wooden plug into the large end of the horn, the hornsmith would cut off the smaller, and still closed, end. He would then whittle a small wooden plug that could be placed into and removed from that end as needed. The horn, with its two wooden plugs in place, would then be soaked in a warm water bath. The bath was intended to soften the material, so that it could be shaved easily, but it also caused the horn to shrink around the wooden plugs and make a tighter seal. The hornsmith would use a sharp knife and scrape the horn's wall. He would scrape a little at a time, every now and then holding the horn up to a light to see how translucent it was becoming. In some cases, as in the powder horn shown above, the scraping of the horn's wall was done in a decorative manner. Enough of the wall would be scraped sufficiently thin to see the amount of powder inside, while allowing some of the horn's wall to retain its natural thickness. Soldiers carrying such a powder horn might use their own knives to carve designs, images or words in the thicker part of the horn's wall without danger of cutting clear through it. In the image below, one can see a slight sideways curve in the horn, in addition to the natural arc from the large end to the small end. Oxen's horn, especially, tended to have such a curve, causing the left and right horns to curve in the opposite direction. This was convenient for the soldier carrying the powder horn because a right-handed man could handle a right-handed horn more easily than a left-handed man could, and vice versa. The curve would also allow the horn to hug the shape of the soldier's body as it hung beside his hip. |

| Below are pictures of two other powder horns believed to date to the time of the American Revolutionary War. Additional powder horns, which date from the late 1700s to the mid-1800s are exhibited in the gallery titled Toys, Farm Tools & The Rest. |