![]() The final step in the process of creating watermarked paper is to install the dandy roll on the paper machine near the wet end. The paper, as it is being formed on the machine, will be only slightly dry before the dandy roll with its embossed brass wire mesh cover makes contact with it to impress its design into the paper.

The final step in the process of creating watermarked paper is to install the dandy roll on the paper machine near the wet end. The paper, as it is being formed on the machine, will be only slightly dry before the dandy roll with its embossed brass wire mesh cover makes contact with it to impress its design into the paper.

![]() In order to understand the positioning of the dandy roll, a brief overview of the papermaking process is necessary. {Note: The description which follows is based on the majority of paper machines in use throughout the United States and elsewhere.}

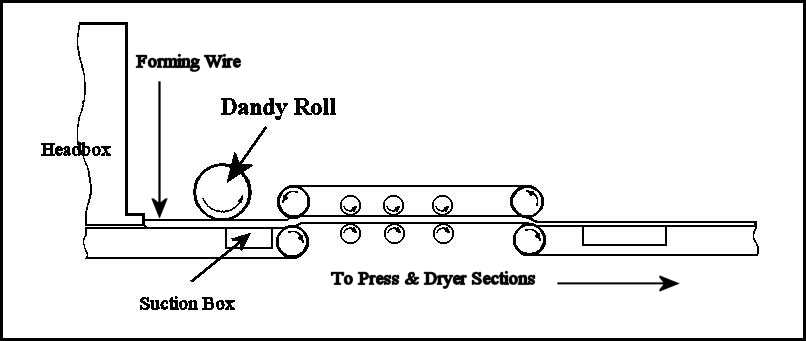

In order to understand the positioning of the dandy roll, a brief overview of the papermaking process is necessary. {Note: The description which follows is based on the majority of paper machines in use throughout the United States and elsewhere.}

![]() The modern paper machine, based on the Fourdrinier model, starts with carefully screened pulp stock (i.e. cleaned and bleached pulp fibers suspended in water) being supplied to the wet end of the machine. The stock is pumped into the head box where it is kept agitated in order to keep the fibers from clumping together, and then sprayed out across the forming wire, an endless fabric belt. At this initial point of contact with the forward moving forming wire, the pulp is shaken laterally, in order to cause a portion of the pulp fibers to alter their direction, and effectively create a mat or web of paper.

The modern paper machine, based on the Fourdrinier model, starts with carefully screened pulp stock (i.e. cleaned and bleached pulp fibers suspended in water) being supplied to the wet end of the machine. The stock is pumped into the head box where it is kept agitated in order to keep the fibers from clumping together, and then sprayed out across the forming wire, an endless fabric belt. At this initial point of contact with the forward moving forming wire, the pulp is shaken laterally, in order to cause a portion of the pulp fibers to alter their direction, and effectively create a mat or web of paper.

![]() The forming wire is supported by the breast roll and a number of table rolls.

The forming wire is supported by the breast roll and a number of table rolls.

![]() The pulp stock, which now is more properly known as the paper stock, being carried forward by the forming wire, passes over a suction box (or a number of them). The suction box pulls a certain amount of the water (anywhere from 5% to 15%) from the paper stock.

The pulp stock, which now is more properly known as the paper stock, being carried forward by the forming wire, passes over a suction box (or a number of them). The suction box pulls a certain amount of the water (anywhere from 5% to 15%) from the paper stock.

![]() The paper stock on the forming wire next passes under the dandy roll before crossing over a suction couch roll which, as its name implies, 'couches', or coaxes, the forming paper off the forming wire and onto a woolen felt or belt by sucking water from it. The word 'couch' comes from the French, meaning to de-water, something. In this case, the suction couch roll de-waters the paper stock by suctioning off the water by means of a vacuum that exists within the roll itself, the water being permitted to pass through a series of holes in the surface of the roll. The removal of the small percentage of water allows the web of paper to release its grip on the fabric of the forming wire.

The paper stock on the forming wire next passes under the dandy roll before crossing over a suction couch roll which, as its name implies, 'couches', or coaxes, the forming paper off the forming wire and onto a woolen felt or belt by sucking water from it. The word 'couch' comes from the French, meaning to de-water, something. In this case, the suction couch roll de-waters the paper stock by suctioning off the water by means of a vacuum that exists within the roll itself, the water being permitted to pass through a series of holes in the surface of the roll. The removal of the small percentage of water allows the web of paper to release its grip on the fabric of the forming wire.

General Diagram Of The Forming Section Of A Paper Machine

![]() The web of forming paper is then passed onto the felt which will carry it between a number of presses which remove more water before passing it on to the dryer section of the paper machine to complete the drying process.

The web of forming paper is then passed onto the felt which will carry it between a number of presses which remove more water before passing it on to the dryer section of the paper machine to complete the drying process.

![]() To return to the dandy roll, it will be noted in the above that the dandy roll is placed above the web of paper after a small amount of water is removed by the suction box. At this point, when the paper stock contains about 85% water, the watermark design can be effectively impressed into it.

To return to the dandy roll, it will be noted in the above that the dandy roll is placed above the web of paper after a small amount of water is removed by the suction box. At this point, when the paper stock contains about 85% water, the watermark design can be effectively impressed into it.

![]() In some cases, the dandy roll is employed to impart an overall pattern to the paper, as noted elsewhere in regard to 'laid' or 'wove' paper by means of special cover fabrics that bear the particular patterns. In other cases, it might be used simply to even out the fibers of the web of paper stock, without imparting any pattern to the paper.

In some cases, the dandy roll is employed to impart an overall pattern to the paper, as noted elsewhere in regard to 'laid' or 'wove' paper by means of special cover fabrics that bear the particular patterns. In other cases, it might be used simply to even out the fibers of the web of paper stock, without imparting any pattern to the paper.

![]() At one time, the dandy roll was driven by the Fourdrinier wire, simply resting on it, and allowing the wire's momentum to turn the dandy roll, but at the present time the dandy roll is generally equipped with its own drive in order to eliminate the drag which may result in distorted watermarks.

At one time, the dandy roll was driven by the Fourdrinier wire, simply resting on it, and allowing the wire's momentum to turn the dandy roll, but at the present time the dandy roll is generally equipped with its own drive in order to eliminate the drag which may result in distorted watermarks.

![]()