![]() Ironmaking in the United States is an old industry; mills for the manufacture of the metal were built in the early years of this nation's existence. In Pennsylvania, the Mount Joy Forge was constructed in 1742 on Valley Creek in what is now Montgomery County. Valley Creek flows northeastward through Chester County to join the Schuylkill River a short distance to the northwest of the city of Philadelphia. It was near the juncture of Valley Creek and the Schuylkill River that the Mount Joy Forge was built some thirty years prior to the outbreak of the American War of Independence. In 1757 the forge was purchased by ironmaster John Potts, who later founded nearby Pottstown in Montgomery County, and who had married Ruth Savage (a step-daughter of Samuel Nutt who built an iron forge on French Creek in 1717). Under the management of John Potts, the Mount Joy Forge would become known as Valley Forge. It was under that latter name that the area near Pott's ironworks would become one of the most famous landmarks of American Independence.

Ironmaking in the United States is an old industry; mills for the manufacture of the metal were built in the early years of this nation's existence. In Pennsylvania, the Mount Joy Forge was constructed in 1742 on Valley Creek in what is now Montgomery County. Valley Creek flows northeastward through Chester County to join the Schuylkill River a short distance to the northwest of the city of Philadelphia. It was near the juncture of Valley Creek and the Schuylkill River that the Mount Joy Forge was built some thirty years prior to the outbreak of the American War of Independence. In 1757 the forge was purchased by ironmaster John Potts, who later founded nearby Pottstown in Montgomery County, and who had married Ruth Savage (a step-daughter of Samuel Nutt who built an iron forge on French Creek in 1717). Under the management of John Potts, the Mount Joy Forge would become known as Valley Forge. It was under that latter name that the area near Pott's ironworks would become one of the most famous landmarks of American Independence.

![]() Earlier than that famous forge's construction, the Bristol Furnace was established on the Rappahannock River in the year 1722. Augustine Washington, the father of George, was an ironmaster who helped start this furnace's operations situated about forty miles south of Fredericksburg, Virginia. Augustine also became involved with the Principio Furnace at the head of the Chesapeake Bay around the year 1726.

Earlier than that famous forge's construction, the Bristol Furnace was established on the Rappahannock River in the year 1722. Augustine Washington, the father of George, was an ironmaster who helped start this furnace's operations situated about forty miles south of Fredericksburg, Virginia. Augustine also became involved with the Principio Furnace at the head of the Chesapeake Bay around the year 1726.

![]() Earlier still, in 1641 in New England, the Company of Undertakers for the Iron Works in New England was formed by some enterprising tradesmen. Associated with this company, the famous furnace town of Saugus, Massachusetts was in full-scale operation in the manufacture of iron by the mid-1650s.

Earlier still, in 1641 in New England, the Company of Undertakers for the Iron Works in New England was formed by some enterprising tradesmen. Associated with this company, the famous furnace town of Saugus, Massachusetts was in full-scale operation in the manufacture of iron by the mid-1650s.

![]() To take the iron industry back even further, we need only look at the Virginia Company's Declaration of the present State of Virginia directed to the King of England in 1623 in defence of the Virginia Charter. In that document the Company's representatives noted that: "During these four last years there hath been expended in setting up of iron works (the oar whereof is there in great plenty and excellent) above five thousand pounds, which being brought in a manner to perfection was greatly interrupted by the late massacre, but ordered to be restored again with all possible dilligence."

To take the iron industry back even further, we need only look at the Virginia Company's Declaration of the present State of Virginia directed to the King of England in 1623 in defence of the Virginia Charter. In that document the Company's representatives noted that: "During these four last years there hath been expended in setting up of iron works (the oar whereof is there in great plenty and excellent) above five thousand pounds, which being brought in a manner to perfection was greatly interrupted by the late massacre, but ordered to be restored again with all possible dilligence."

![]() The most basic definition of ironmaking is: the extraction of pure iron from the mineral bearing ore. Iron is present, in the earth's surface as a mixture with other minerals and also with oxygen. The purpose of the iron furnace is to heat the ore to the point where a substance known as "slag" would form out of the other minerals, allowing the molten iron to flow free.

The most basic definition of ironmaking is: the extraction of pure iron from the mineral bearing ore. Iron is present, in the earth's surface as a mixture with other minerals and also with oxygen. The purpose of the iron furnace is to heat the ore to the point where a substance known as "slag" would form out of the other minerals, allowing the molten iron to flow free.

![]() Four basic ingredients are required for the manufacture of iron. The first ingredient, of course, is iron-bearing ore in good quantity. Any area which held a large quantity of iron-bearing ore would be a good candidate for the iron industry, but the second ingredient, lime, was also very important to the process. If lime was difficult to obtain in large amounts, whether in the form of limestone or oyster shells, an iron furnace would not be able to operate profitably. The lime was required to act as a flux to separate the non-iron material in the ore from the pure iron. It did this by having the attribute of drawing the non-metallic minerals to itself to form the slag ~ a brittle material that often is the only remaining evidence of an ironworks site (because it would be piled into slagheaps, dark mounds on which no plant life except the hardiest weeds can grow). The sight of these manmade hills, barren and rough, is a familiar one through areas which were once home to forges and furnaces; they are often seen in the vicinity of a limestone quarry cutting into the verdant hillside. The third ingredient is wood, which was necessary to supply a source of heat at a time when coal, oil and natural gas were just being discovered. Water, the final and fourth ingredient, supplied power to operate bellows which pumped air ~ and the required oxygen ~ into the furnace, making high heat possible.

Four basic ingredients are required for the manufacture of iron. The first ingredient, of course, is iron-bearing ore in good quantity. Any area which held a large quantity of iron-bearing ore would be a good candidate for the iron industry, but the second ingredient, lime, was also very important to the process. If lime was difficult to obtain in large amounts, whether in the form of limestone or oyster shells, an iron furnace would not be able to operate profitably. The lime was required to act as a flux to separate the non-iron material in the ore from the pure iron. It did this by having the attribute of drawing the non-metallic minerals to itself to form the slag ~ a brittle material that often is the only remaining evidence of an ironworks site (because it would be piled into slagheaps, dark mounds on which no plant life except the hardiest weeds can grow). The sight of these manmade hills, barren and rough, is a familiar one through areas which were once home to forges and furnaces; they are often seen in the vicinity of a limestone quarry cutting into the verdant hillside. The third ingredient is wood, which was necessary to supply a source of heat at a time when coal, oil and natural gas were just being discovered. Water, the final and fourth ingredient, supplied power to operate bellows which pumped air ~ and the required oxygen ~ into the furnace, making high heat possible.

![]() The preparation of the limestone for use in the iron furnace involved the process known as lime burning. In this process, the limeburner would construct a large brick or stone pot-shaped kiln which had a small hole in the bottom and an open top. The bottom of the kiln was filled with brushwood which needed to be dried sufficiently to catch fire. A layer of charcoal (or later, coal) would be placed on top of this, and on top of that would be placed pieces of broken limestone. The limeburner would set fire to the brushwood through the bottom hole. As soon as it ignited, it would be left alone to burn. When it had burned itself out and cooled, the contents would be raked out through the bottom hole. In some cases, the cost of constructing the kiln would be prohibitive, so the limestone would be burned in the open. A foot or two of the brushwood would be laid upon the open ground, over which a six-inch layer of broken limestone would be laid. Another layer of brushwood, and another layer of broken limestone would be added on top. This was continued until the most manageable height would be obtained. The entire pile would be covered with a layer of mud so as to plaster the entire pile into its own air-tight kiln. A hole for starting the fire and also for raking out the lime would be formed on the windward side of the mound. Two or more small holes would be formed near the top of the mound on the leeward side. The brushwood at the bottom would be ignited and the pile left to burn itself out as in the constructed kiln process.

The preparation of the limestone for use in the iron furnace involved the process known as lime burning. In this process, the limeburner would construct a large brick or stone pot-shaped kiln which had a small hole in the bottom and an open top. The bottom of the kiln was filled with brushwood which needed to be dried sufficiently to catch fire. A layer of charcoal (or later, coal) would be placed on top of this, and on top of that would be placed pieces of broken limestone. The limeburner would set fire to the brushwood through the bottom hole. As soon as it ignited, it would be left alone to burn. When it had burned itself out and cooled, the contents would be raked out through the bottom hole. In some cases, the cost of constructing the kiln would be prohibitive, so the limestone would be burned in the open. A foot or two of the brushwood would be laid upon the open ground, over which a six-inch layer of broken limestone would be laid. Another layer of brushwood, and another layer of broken limestone would be added on top. This was continued until the most manageable height would be obtained. The entire pile would be covered with a layer of mud so as to plaster the entire pile into its own air-tight kiln. A hole for starting the fire and also for raking out the lime would be formed on the windward side of the mound. Two or more small holes would be formed near the top of the mound on the leeward side. The brushwood at the bottom would be ignited and the pile left to burn itself out as in the constructed kiln process.

![]() The lime that was produced by burning the limestone needed to be slaked before it could be used in the iron furnace. This involved leaving the lime in small piles out in the open air where it would be rained upon. The reaction of the water on the lime would produce calcium hydroxide or slaked lime, which would then be ready for the iron furnace to act as flux.

The lime that was produced by burning the limestone needed to be slaked before it could be used in the iron furnace. This involved leaving the lime in small piles out in the open air where it would be rained upon. The reaction of the water on the lime would produce calcium hydroxide or slaked lime, which would then be ready for the iron furnace to act as flux.

![]() The third ingredient necessary for a successful ironworks ~ wood ~ was something that has always been a vital and abundant natural resource in North America. It should be noted that usually it was this single ingredient which spelled the doom of a local ironworks ~ when the wood ran out, the cost to operate the industry by importing fuel would be too prohibitive to continue, and the furnace would be shut down to be relocated elsewhere.

The third ingredient necessary for a successful ironworks ~ wood ~ was something that has always been a vital and abundant natural resource in North America. It should be noted that usually it was this single ingredient which spelled the doom of a local ironworks ~ when the wood ran out, the cost to operate the industry by importing fuel would be too prohibitive to continue, and the furnace would be shut down to be relocated elsewhere.

![]() The wood was converted to charcoal, which provided a better form of fuel to heat and melt the iron-ore, and that conversion was accomplished by the collier. As the collier was covered in another page on this website, the method of producing charcoal will not be repeated here.

The wood was converted to charcoal, which provided a better form of fuel to heat and melt the iron-ore, and that conversion was accomplished by the collier. As the collier was covered in another page on this website, the method of producing charcoal will not be repeated here.

![]() Click on the following link to access the Collier Page.

Click on the following link to access the Collier Page. ![]()

![]() In the latter part of the nineteenth century, the collier's job was gradually taken over by the coal industry. As coal became more widely mined and its use also increased, it was only a matter of time till industry switched to coal over the less reliable charcoal. By that time the charcoal colliers had virtually stripped the eastern seaboard of its virgin forests. Iron furnaces and forges tended to shut down their operations in areas stripped of their wood resource and to relocate closer to the coal fields.

In the latter part of the nineteenth century, the collier's job was gradually taken over by the coal industry. As coal became more widely mined and its use also increased, it was only a matter of time till industry switched to coal over the less reliable charcoal. By that time the charcoal colliers had virtually stripped the eastern seaboard of its virgin forests. Iron furnaces and forges tended to shut down their operations in areas stripped of their wood resource and to relocate closer to the coal fields.

![]() The fourth and final ingredient necessary for the manufacture of iron was a resource that was more easily replenished than wood. The water necessary to turn a water wheel, which in turn was necessary to operate a number of pieces of equipment including air bellows, was the one ingredient that almost any area had in plentiful supply. If the other three ingredients were to be located, this fourth one was seldom a problem to the early ironmasters.

The fourth and final ingredient necessary for the manufacture of iron was a resource that was more easily replenished than wood. The water necessary to turn a water wheel, which in turn was necessary to operate a number of pieces of equipment including air bellows, was the one ingredient that almost any area had in plentiful supply. If the other three ingredients were to be located, this fourth one was seldom a problem to the early ironmasters.

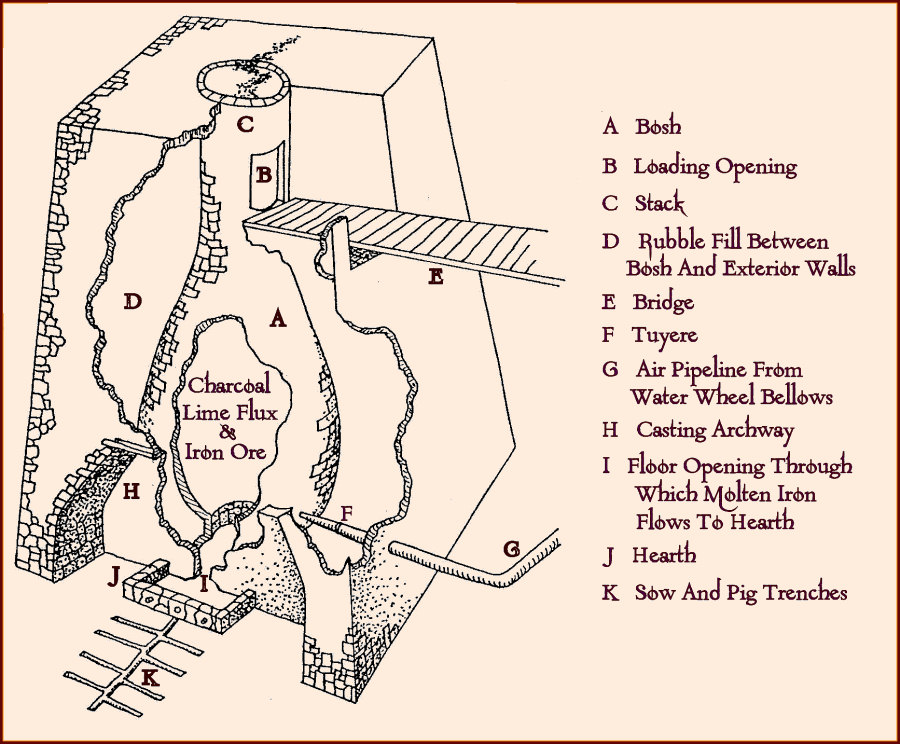

![]() The water was directed over the wheel in the same manner as in a grist mill. This explains why so many older grist mills were purchased by the ironmasters and then converted to the furnace's needs ~ it was cheaper to purchase a preexisting mill than to go to the expense of constructing the necessary dam, raceways and wheel to perform that function. Large bellows, like those employed in a blacksmith's forge, were operated by cams attached to the water wheel's shaft. After 1820, cylindrical bellows were introduced which increased the capacity of air. These were constructed in the form of barrels which had air pipes leading out from both ends and a diaphragm in the center. As the cams moved the diaphragm, the air was pushed out first one end of the barrel and then out the other end so that a double amount of air was sent to the furnace. The air was piped to the bosh, which was the actual furnace itself, and which consisted of an egg-shaped structure into which the four ingredients (iron ore, lime, charcoal and water ~ in the form of air) were fed. As the water turned the wheel, causing the cams to compress the bellows alternately, the constant force sent a steady supply of air surging into the bosh. As long as this supply of air held, that is until the mill pond froze over causing the wheel to halt, and as long as the supply of the other ingredients held out, the furnace would remain firing. It was not uncommon for the firing to last thirty to forty weeks on end, or in other words, year-round.

The water was directed over the wheel in the same manner as in a grist mill. This explains why so many older grist mills were purchased by the ironmasters and then converted to the furnace's needs ~ it was cheaper to purchase a preexisting mill than to go to the expense of constructing the necessary dam, raceways and wheel to perform that function. Large bellows, like those employed in a blacksmith's forge, were operated by cams attached to the water wheel's shaft. After 1820, cylindrical bellows were introduced which increased the capacity of air. These were constructed in the form of barrels which had air pipes leading out from both ends and a diaphragm in the center. As the cams moved the diaphragm, the air was pushed out first one end of the barrel and then out the other end so that a double amount of air was sent to the furnace. The air was piped to the bosh, which was the actual furnace itself, and which consisted of an egg-shaped structure into which the four ingredients (iron ore, lime, charcoal and water ~ in the form of air) were fed. As the water turned the wheel, causing the cams to compress the bellows alternately, the constant force sent a steady supply of air surging into the bosh. As long as this supply of air held, that is until the mill pond froze over causing the wheel to halt, and as long as the supply of the other ingredients held out, the furnace would remain firing. It was not uncommon for the firing to last thirty to forty weeks on end, or in other words, year-round.

![]() In regard to the actual operation of the iron furnace, the construction and layout of a typical one should be noted. Because the iron ore, lime used for flux, and the charcoal were loaded into the top of the bosh, it was necessary to construct the furnace against the side of a hill. The bosh was constructed of stone lined inside with either sandstone or manufactured firebrick. A maximum height of thirty-five feet was set for the bosh and its stack. Any higher, the volume of ore would crush the charcoal, causing it to choke off any draft. An inside width of six to eight feet at the widest point narrowed to only a few feet at the mouth of the stack. This stone bosh would be supported by stone rubble which was contained within four stone exterior walls which took the form of a truncated pyramid. At the base of the one exterior wall an arch would be constructed from which the casting hearth extended at the ground level. Another opening would be part of the structure: the tuyere arch. This was not really an archway but rather simply an opening through which the tuyere would be laid. The tuyere was a four-foot long iron or steel conical tube which fit onto the air supply piping at its widest end. The purpose of this was to compress the size of the opening through which the air would pass and in so doing would increase its pressure just before it entered the furnace proper. With the only opening for loading the ore, flux and charcoal being at the top of the stack, a bridge (of either wood or ground) would pass from the adjacent hillside to the top of the pyramid-shaped furnace structure. Early furnaces were loaded directly into the open end of the stack. Later, iron furnaces would be constructed with a loading opening in the side of the stack below the top so that the fuel and ore could be loaded into the bosh without being in a direct line with the harmful exhaust gases that were flowing out of the stack opening.

In regard to the actual operation of the iron furnace, the construction and layout of a typical one should be noted. Because the iron ore, lime used for flux, and the charcoal were loaded into the top of the bosh, it was necessary to construct the furnace against the side of a hill. The bosh was constructed of stone lined inside with either sandstone or manufactured firebrick. A maximum height of thirty-five feet was set for the bosh and its stack. Any higher, the volume of ore would crush the charcoal, causing it to choke off any draft. An inside width of six to eight feet at the widest point narrowed to only a few feet at the mouth of the stack. This stone bosh would be supported by stone rubble which was contained within four stone exterior walls which took the form of a truncated pyramid. At the base of the one exterior wall an arch would be constructed from which the casting hearth extended at the ground level. Another opening would be part of the structure: the tuyere arch. This was not really an archway but rather simply an opening through which the tuyere would be laid. The tuyere was a four-foot long iron or steel conical tube which fit onto the air supply piping at its widest end. The purpose of this was to compress the size of the opening through which the air would pass and in so doing would increase its pressure just before it entered the furnace proper. With the only opening for loading the ore, flux and charcoal being at the top of the stack, a bridge (of either wood or ground) would pass from the adjacent hillside to the top of the pyramid-shaped furnace structure. Early furnaces were loaded directly into the open end of the stack. Later, iron furnaces would be constructed with a loading opening in the side of the stack below the top so that the fuel and ore could be loaded into the bosh without being in a direct line with the harmful exhaust gases that were flowing out of the stack opening.

![]() Successive layers of charcoal, iron ore and lime flux would be dumped into the stack so that the bosh would be kept full, day and night. As the iron ore separated into the pure molten metal and the lime/slag aggregate, the molten iron would flow into the casting hearth. The hearth consisted basically of a contained area of the floor at the main archway which was dammed up by stone to hold the molten metal. In the normal course of firing the furnace, this hearth would fill up with molten iron at least two times during a twenty-four hour period. It would be emptied by a gutterman who would knock out an easily broken clay plug in a hole in the side of the dam. When the outside air hit the molten metal, a loud explosion of sound would boom through the vicinity of the furnace. When the discharge thundered, the furnace was said to be "in blast". The loud blast could be hear for miles around. The molten metal would flow into a trench system dug in the sand floor surrounding the casting hearth. The trenches were dug with a triangular-shaped hoe and were known as pig trenches. (The iron which filled the pig trenches would then be referred to as pigiron.) The main trench that extended from the hearth in a long, straight line was known as the sow and smaller trenches that branched off the sides of the main sow trench were called the pig trenches. When the clay plug in the hearth side would be broken, the molten iron would flow down the sow and into each of the pig trenches. It was left there to bubble as it cooled. In the meantime, the gutterman would dig another system of trenches on the opposite side of the hearth for the next flow of metal. When it was sufficiently cool to handle, the pigs or pigiron was broken off of the sow and the sow likewise was broken up into more manageable lengths to be transported to foundries.

Successive layers of charcoal, iron ore and lime flux would be dumped into the stack so that the bosh would be kept full, day and night. As the iron ore separated into the pure molten metal and the lime/slag aggregate, the molten iron would flow into the casting hearth. The hearth consisted basically of a contained area of the floor at the main archway which was dammed up by stone to hold the molten metal. In the normal course of firing the furnace, this hearth would fill up with molten iron at least two times during a twenty-four hour period. It would be emptied by a gutterman who would knock out an easily broken clay plug in a hole in the side of the dam. When the outside air hit the molten metal, a loud explosion of sound would boom through the vicinity of the furnace. When the discharge thundered, the furnace was said to be "in blast". The loud blast could be hear for miles around. The molten metal would flow into a trench system dug in the sand floor surrounding the casting hearth. The trenches were dug with a triangular-shaped hoe and were known as pig trenches. (The iron which filled the pig trenches would then be referred to as pigiron.) The main trench that extended from the hearth in a long, straight line was known as the sow and smaller trenches that branched off the sides of the main sow trench were called the pig trenches. When the clay plug in the hearth side would be broken, the molten iron would flow down the sow and into each of the pig trenches. It was left there to bubble as it cooled. In the meantime, the gutterman would dig another system of trenches on the opposite side of the hearth for the next flow of metal. When it was sufficiently cool to handle, the pigs or pigiron was broken off of the sow and the sow likewise was broken up into more manageable lengths to be transported to foundries.

![]() Some direct casting was performed at the iron furnaces but this was limited to large articles such as kettles and the like. For the most part, the iron produced at the iron furnace was sold to foundries or to local blacksmiths who would rework and refine the metal into the articles of their craft. In some cases, a forge would be constructed in the vicinity of the furnace so that the pigiron could be refined right there. In the forge, the raw pigiron would be heated and hammered into blooms of wrought iron which was more readily used by blacksmiths and foundries.

Some direct casting was performed at the iron furnaces but this was limited to large articles such as kettles and the like. For the most part, the iron produced at the iron furnace was sold to foundries or to local blacksmiths who would rework and refine the metal into the articles of their craft. In some cases, a forge would be constructed in the vicinity of the furnace so that the pigiron could be refined right there. In the forge, the raw pigiron would be heated and hammered into blooms of wrought iron which was more readily used by blacksmiths and foundries.

![]() The function of the forge was to remove as much carbon from the iron as possible. This required reheating the pigiron and slagging off the impurities and then hammering it to give it some temper and strength. At the bottom level of the forge sat a large stone crucible structure. This crucible would be filled with old slag, and a charcoal fire would be built on top of that. The pigiron would be pushed into the forge. As it melted, it would displace the slag and fill up the crucible. It continued to cook for about an hour, during which time a worker by the name of finer would stir it with an iron bar. The stirring would cause any carbon in the molten metal to rise to the surface. When the carbon reached the surface, it would react with the oxygen in the air, and would burst into flame and consume itself. When the mass stopped flaming, and it was assumed that all the carbon was removed, the molten iron would be allowed to cool, creating a mass called the loop. This loop was removed from the crucible by use of iron tongs and any slag or charcoal that stuck to it would be knocked off with sledge hammers.

The function of the forge was to remove as much carbon from the iron as possible. This required reheating the pigiron and slagging off the impurities and then hammering it to give it some temper and strength. At the bottom level of the forge sat a large stone crucible structure. This crucible would be filled with old slag, and a charcoal fire would be built on top of that. The pigiron would be pushed into the forge. As it melted, it would displace the slag and fill up the crucible. It continued to cook for about an hour, during which time a worker by the name of finer would stir it with an iron bar. The stirring would cause any carbon in the molten metal to rise to the surface. When the carbon reached the surface, it would react with the oxygen in the air, and would burst into flame and consume itself. When the mass stopped flaming, and it was assumed that all the carbon was removed, the molten iron would be allowed to cool, creating a mass called the loop. This loop was removed from the crucible by use of iron tongs and any slag or charcoal that stuck to it would be knocked off with sledge hammers.

![]() While the loop was still pretty hot, it would be handled to the tilt hammer. Powered by cogs and gears from the same water wheel shaft that provided the forced air draft to increase and maintain the heat of the forge's crucible, the tilt hammer was raised and let fall onto the loop. The tilt hammer was constructed with a large stone or previously worked head of iron attached to a heavy wooden beam. The sheer weight of the hammer head was enough to hammer the temper back into the heated metal lump. After the loop was hammered once into a bar shape, it would be removed and placed into another forge. Here it would be heated to a white-hot state. While in that condition it would divided into smaller masses and they in turn would be removed from the forge's heat and taken to the tilt hammer. Rehammering and reheating the pigiron would eventually force all the impurities and air pockets out of the metal while tempering it to great strength. The iron bars produced by the forge were usually made to a standard size of: one-and-a-half inches thick by three inches wide, by eight feet long. The larger but hammered loops were called blooms of iron while these further refined eight-foot long bars were known as merchantable bar-iron.

While the loop was still pretty hot, it would be handled to the tilt hammer. Powered by cogs and gears from the same water wheel shaft that provided the forced air draft to increase and maintain the heat of the forge's crucible, the tilt hammer was raised and let fall onto the loop. The tilt hammer was constructed with a large stone or previously worked head of iron attached to a heavy wooden beam. The sheer weight of the hammer head was enough to hammer the temper back into the heated metal lump. After the loop was hammered once into a bar shape, it would be removed and placed into another forge. Here it would be heated to a white-hot state. While in that condition it would divided into smaller masses and they in turn would be removed from the forge's heat and taken to the tilt hammer. Rehammering and reheating the pigiron would eventually force all the impurities and air pockets out of the metal while tempering it to great strength. The iron bars produced by the forge were usually made to a standard size of: one-and-a-half inches thick by three inches wide, by eight feet long. The larger but hammered loops were called blooms of iron while these further refined eight-foot long bars were known as merchantable bar-iron.

![]() The slag that had accumulated in the firing process of either the furnace or the forge would have to be removed from time to time. This was accomplished by making use of another opening near the base of the bosh. This cinder hole was located at a height above the hearth since the slag would float onto the surface of the molten iron. About every hour the cinder hole was opened up so that the slag could be raked out. This was carried by wheelbarrow to be deposited on the overgrowing slagheap on the outer edge of the furnace property.

The slag that had accumulated in the firing process of either the furnace or the forge would have to be removed from time to time. This was accomplished by making use of another opening near the base of the bosh. This cinder hole was located at a height above the hearth since the slag would float onto the surface of the molten iron. About every hour the cinder hole was opened up so that the slag could be raked out. This was carried by wheelbarrow to be deposited on the overgrowing slagheap on the outer edge of the furnace property.